Drying Period

Lamination > Drying Period

After lamination, it's crucial to allow the laminated touch sensor and glass to dry undisturbed for 24 hours in a clean, controlled environment.

Drying Procedure

-

Place the laminated assembly flat, with the touch sensor side facing up.

-

Do not touch or manipulate the sensor during this drying time.

-

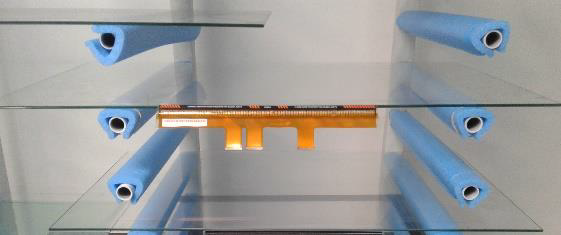

Ensure the surface it rests on is soft and non-abrasive—ideally foam-covered (see Fig. 18).

Recommended Environmental Conditions

To ensure proper bonding and avoid issues like bubbles or delamination:

-

Air temperature: Between 20°C and 25°C

-

Relative humidity: Between 30% and 45%

-

Drying time: Minimum of 24 hours

If possible, perform this step in a room with air conditioning or climate control, to maintain a stable environment.

Fig. 18 - Drying rack

Fig. 18 - Drying rack

Related Articles

Drying Period

Lamination Drying Period Leave the laminated touch sensor and glass to dry for 24 hours in a suitable, clean area, placing it flat, touch sensor side facing up. Do not touch the touch sensor while it is drying. Ideally, the drying area should have ...Placing the Touch Sensor on the Glass

How to place the Displax touch sensor on the glass After removing the protective liner, you must gently transfer the touch sensor from the wall to the glass substrate. This step requires care to avoid wrinkles, folds, or grid misalignment. Step 1 – ...Solution and Care

How do I prepare the solution to laminate a Displax touch sensor? To properly laminate a Displax touch sensor onto a glass substrate, you must prepare a MIX solution that allows for repositioning and air-bubble-free installation. MIX Solution – Water ...Post-Drying Cleaning Process

Cleaning Process Once the 24-hour drying period is complete, the laminated touch sensor is ready for a final cleaning step to ensure optimal transparency and touch performance. Cleaning Instructions Use a soft, lint-free cloth (e.g., microfiber). ...Testing Before Lamination

How do I test Ultra & Fit touch sensors before lamination? Why testing is important Before laminating the touch sensor, it's crucial to test it for: Shipping-related damage (rare but possible) Compatibility or interference with the glass or surface ...